Cct Diagram Theory Of Alloys And Alloys Diagrams Material Technology

Cct Diagram Theory Of Alloys And Alloys Diagrams Material Subject material technology video name cct diagram chapter theory of alloys and alloys diagrams faculty prof. k krishna kishoreupskill and get place. Cct diagram. this diagram is not a unique diagram like ttt diagram for a material. it depends on type of cooling. this diagram can predict phase transformation information if similar cooling curves had been used during its determination or if equivalent cooling schedule are used during process of production. 11.

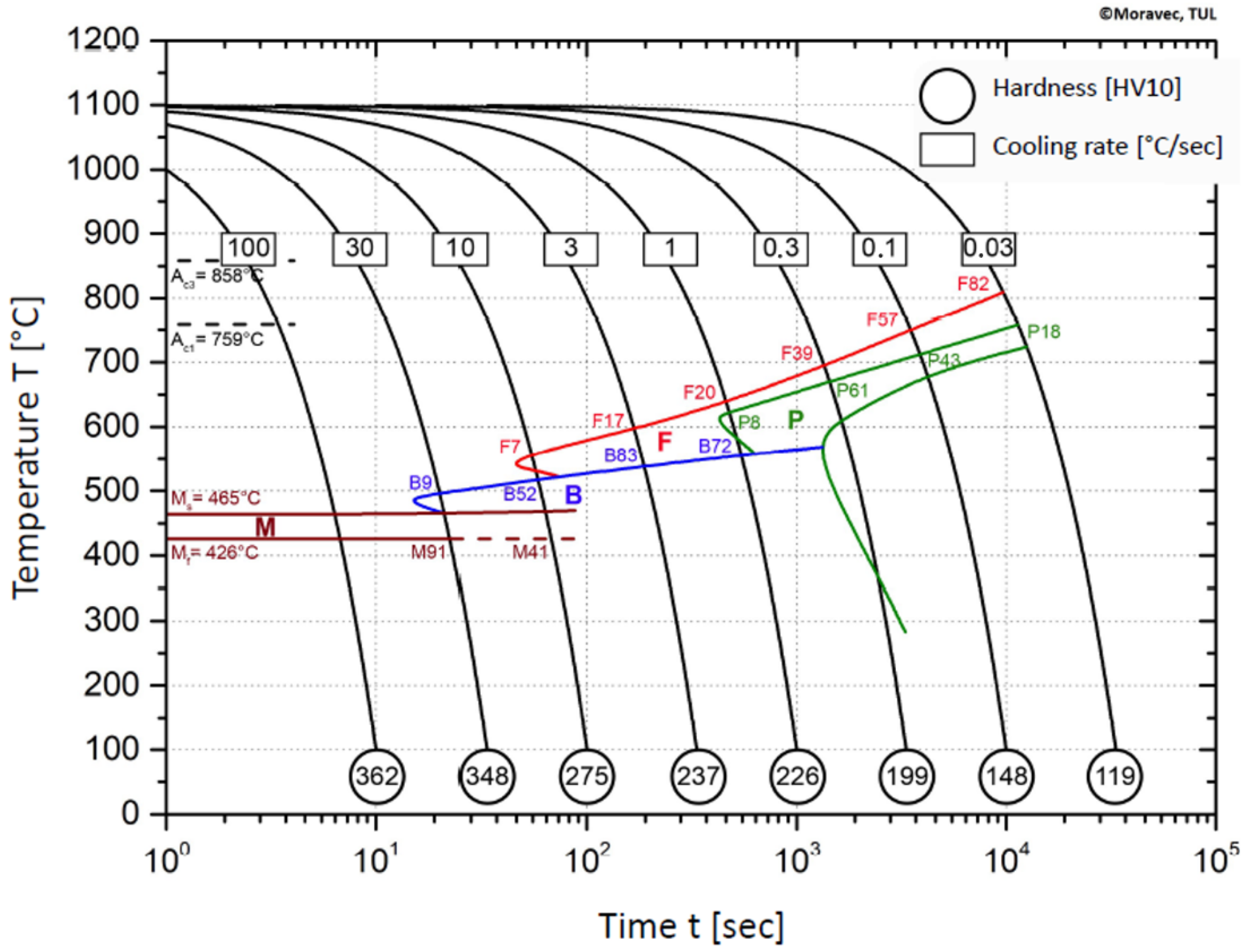

Cct Diagram Obtained For The A Base Alloy And B B Alloy Download Continuous cooling transformation (cct) diagrams are widely used when heat treating steels and represent which type of phase will occur in a material as it is cooled at different cooling rates. cct diagrams are constructed on the basis of dilatometry measurements on relatively small testing samples (cylindrical shape with diameter of 4mm and length of 11 mm in this study). the main aim of this. However, traditional cct diagrams are developed based on slow and monotonic cooling processes such as furnace cooling and air cooling, which are greatly different from the repetitive heating and cooling processes in am. in this study, a new general methodology is presented to create cct diagrams for materials fabricated by am. A continuous cooling transformation (cct) phase diagram is often used when heat treating steel. [ 1 ] these diagrams are used to represent which types of phase changes will occur in a material as it is cooled at different rates. these diagrams are often more useful than time temperature transformation diagrams because it is more convenient to. In matilda ® ’s cct database, experimentally recorded and standardized cct and ttt diagrams are available in a digital library for a large number of steel grades: • ttt diagrams. information on the austenitizing temperatures and the austenitizing time as well as the exact chemical analysis can be displayed in the cct database.

Materials Free Full Text Determination Of Cct Diagram By A continuous cooling transformation (cct) phase diagram is often used when heat treating steel. [ 1 ] these diagrams are used to represent which types of phase changes will occur in a material as it is cooled at different rates. these diagrams are often more useful than time temperature transformation diagrams because it is more convenient to. In matilda ® ’s cct database, experimentally recorded and standardized cct and ttt diagrams are available in a digital library for a large number of steel grades: • ttt diagrams. information on the austenitizing temperatures and the austenitizing time as well as the exact chemical analysis can be displayed in the cct database. The interaction of different alloying elements has a significant impact on the mechanical and microstructural properties of steel products due to the thermodynamic and kinetic effect. this article presents a statistically developed and validated model for austenite decomposition during cooling, based on a set of experimental continuous cooling transformation diagrams available in literature. Using ssdta on the experimentally determined cooling curves and on the basis of cct diagrams for weld metals of similar chemical composition [49], a welding cct diagram was created for the weld.

Cct Diagram Steel Material Science Mechanical Engineering Diagram The interaction of different alloying elements has a significant impact on the mechanical and microstructural properties of steel products due to the thermodynamic and kinetic effect. this article presents a statistically developed and validated model for austenite decomposition during cooling, based on a set of experimental continuous cooling transformation diagrams available in literature. Using ssdta on the experimentally determined cooling curves and on the basis of cct diagrams for weld metals of similar chemical composition [49], a welding cct diagram was created for the weld.

Comments are closed.