Basic Hydrotesting Procedure Pressure Test Paano Gumawa Mg Testing

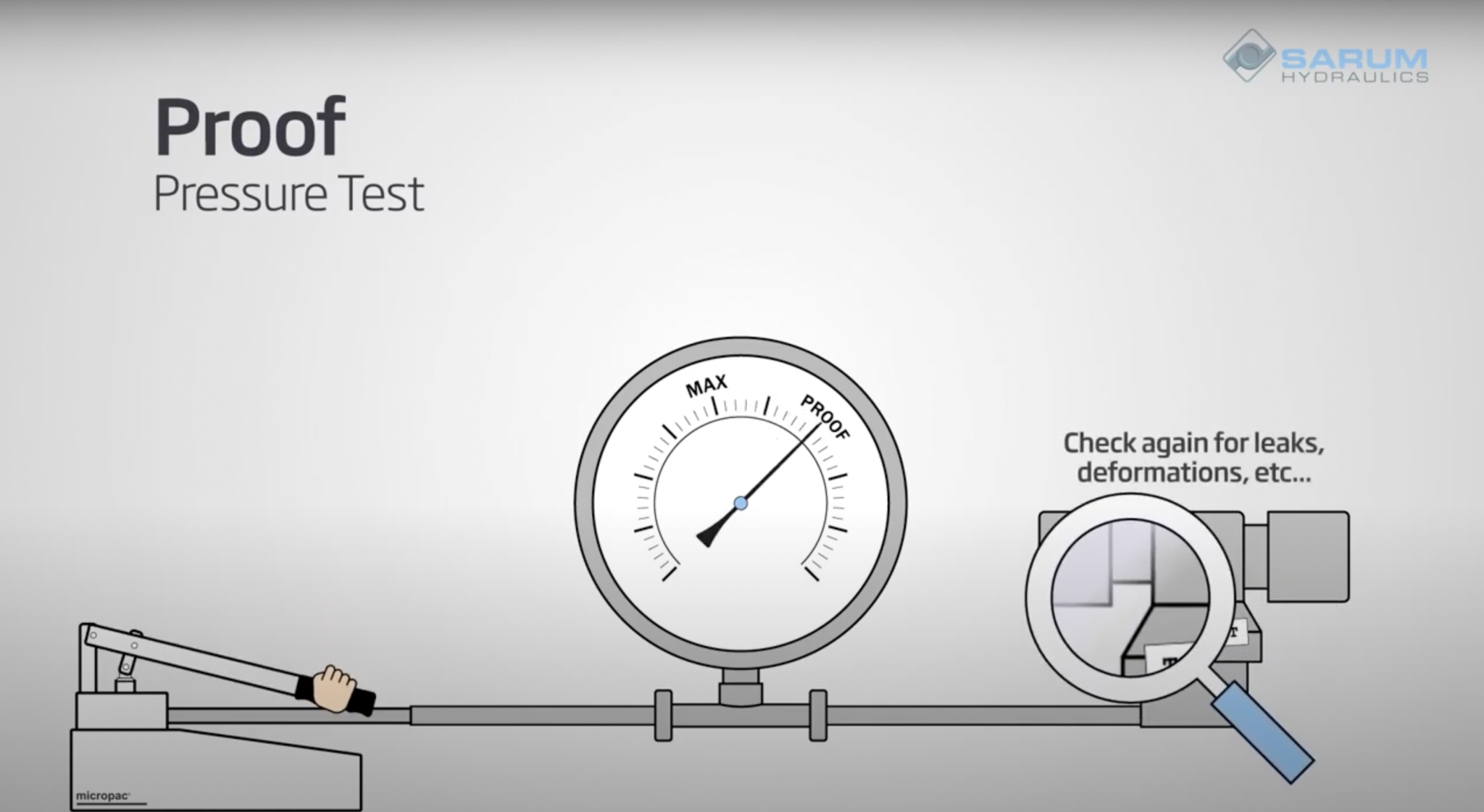

Basic Hydrotesting Procedure Pressure Test Paano Gumawa Mg Testing #hydrotest#pressuretest. The pressure in the system should be gradually increased to 0.5 times the test pressure, then increase in 1 10th of the test pressure increments until obtaining the appropriate test pressure. for at least 10 minutes, technicians must maintain the test pressure. it can then decrease to the design pressure, allowing for a leakage test.

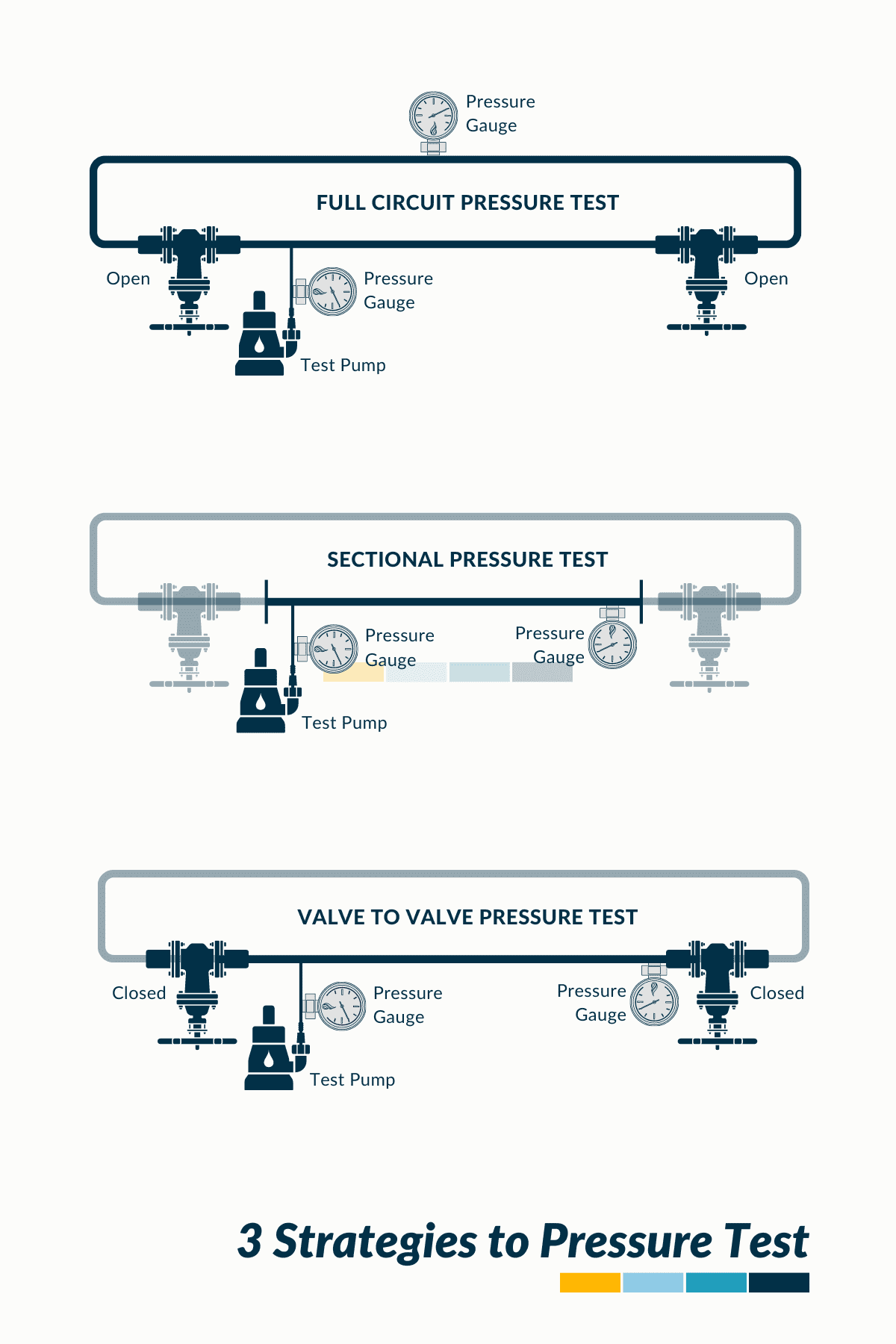

Hydraulic Pressure Testing Explained With Templates 52 Off Hydro testing of pipelines procedure62. hydro – testing of pipelines procedurehydro testing (hydrostatic testing) is a type of test that is performed on pressure vessels to check for. leaks and correct mechanical properties. it involves completely filing up a pressure ve. office or division: construction and maintenance division. The testing process and its challenges. during the hydrotesting process, the internal pressure of the pipeline is continuously monitored. this monitoring is crucial to detect any potential leaks or weaknesses in the pipeline structure. advanced testing equipment is used to ensure accurate and reliable readings throughout the test. Test pressure shall be according to table 1 of this procedure. all lines and appurtenances which do not form part of the test system shall be removed or otherwise isolated from the test system before the test. blind flanges and gaskets shall be installed as necessary. all fitting shall be tightened expect the vent points. To calculate the actual testing pressure that the system will be exposed to, use the following: htp = mwsp x 1.5. where: htp = hydraulic testing pressure. mwsp = maximum working system pressure. 1.5 = as per besa tr 6. 🚀 hydraulic testing pressure calculation example. a chilled water system has a maximum working system pressure [mwsp] of 245kpa.

Hydrostatic Testing How To Pressure Testing Hydro Test Youtube Test pressure shall be according to table 1 of this procedure. all lines and appurtenances which do not form part of the test system shall be removed or otherwise isolated from the test system before the test. blind flanges and gaskets shall be installed as necessary. all fitting shall be tightened expect the vent points. To calculate the actual testing pressure that the system will be exposed to, use the following: htp = mwsp x 1.5. where: htp = hydraulic testing pressure. mwsp = maximum working system pressure. 1.5 = as per besa tr 6. 🚀 hydraulic testing pressure calculation example. a chilled water system has a maximum working system pressure [mwsp] of 245kpa. The general requirements of pressure testing encompass several key aspects: 1. stress exceeding yield strength. when the stress on the material exceeds its yield strength, the test pressure should be reduced to a level that will not surpass the yield strength at the temperature of testing. The hydrostatic test procedure for pipelines is systematic and thorough. initially, the pipeline is cleared of any contents and carefully inspected for visible damage or defects. then, it is filled with water, and the pressure is gradually increased to the specified test pressure. this pressure is maintained for a predetermined period to.

Hydraulic Pressure Testing Explained With Templates 52 Off The general requirements of pressure testing encompass several key aspects: 1. stress exceeding yield strength. when the stress on the material exceeds its yield strength, the test pressure should be reduced to a level that will not surpass the yield strength at the temperature of testing. The hydrostatic test procedure for pipelines is systematic and thorough. initially, the pipeline is cleared of any contents and carefully inspected for visible damage or defects. then, it is filled with water, and the pressure is gradually increased to the specified test pressure. this pressure is maintained for a predetermined period to.

Hydraulic Pressure Testing Explained With Templates 52 Off

Comments are closed.