Automated Visual Equipment Hardware Smd Smt Production Line Automatic

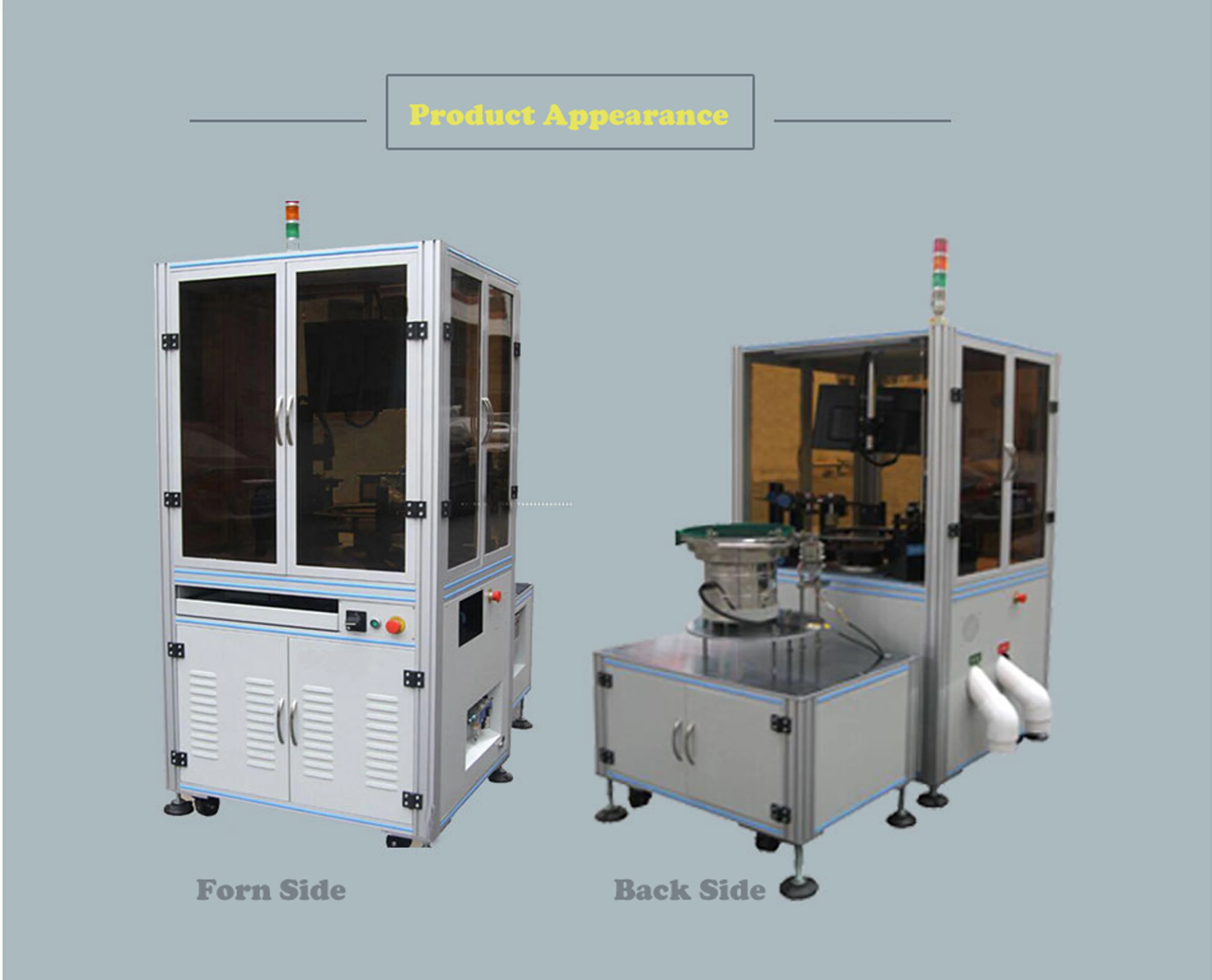

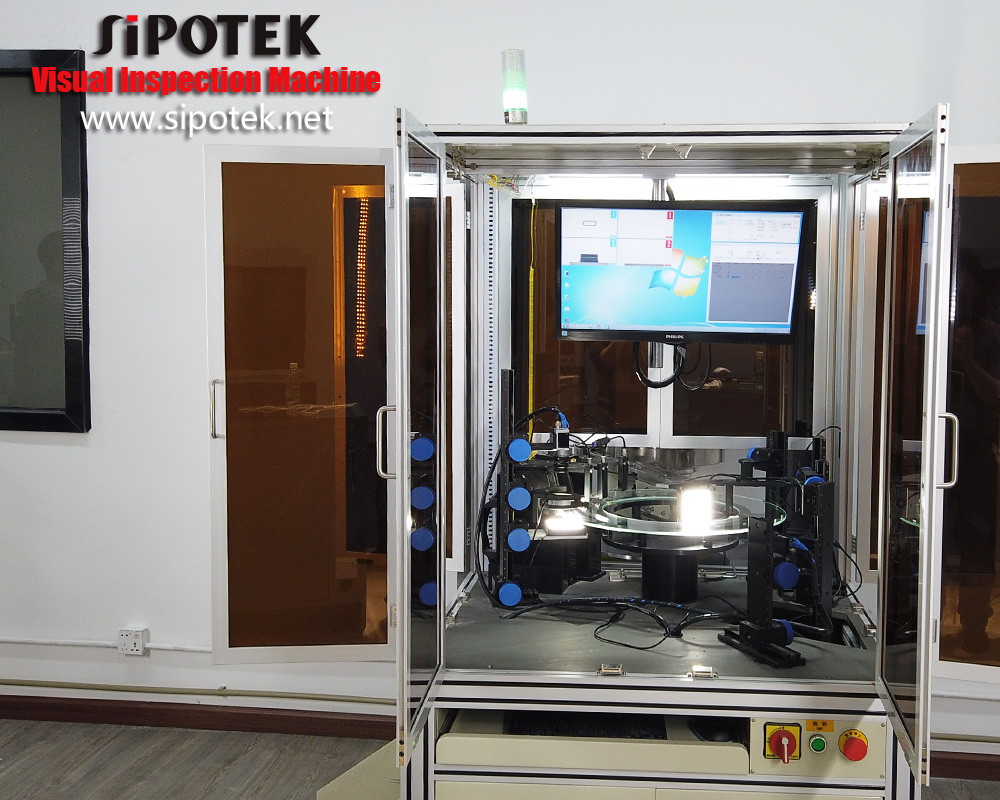

Automated Visual Equipment Hardware Smd Smt Production Line Automatic Description automated visual equipment hardware smd smt production line automatic optical inspection system aoi machine vision measuring product 86 13352636504 [email protected] 86 13352636504 9:00 am 6:00pm. Sipotek t300 automated visual equipment hardware smd smt production line automatic optical inspection system by shenzhen sipotek technology co., ltd automated visual equipment hardware smd smt production line automatic optical inspection system.

Automated Visual Equipment Hardware Smd Smt Production Line Automatic The smt assembly line, commonly known as the smt line, allows for automated mass production of printed circuit board (pcb) assemblies with great precision and speed. this article provides a comprehensive overview of smt lines, how they work, costs, and choosing the right smt line manufacturer. Smt line & automatic soldering machines. surface mount technology (smt) is a method in which the components are mounted or placed directly onto the surface of a printed circuit board (pcb). an electronic device so made is called a surface mount device (smd). the smt line consists of specially selected equipment, a solder paste screen printer or. Visual inspection system. sony manufactures and markets a full line of professional and industrial ccd cameras, including gige, smart, 1394.b, camera link®, analog b w, color, high speed progressive scan, network, block and video conferencing cameras. from machine vision, factory automation and inspection, to security and process control, sony. Automated optical inspection (aoi) is an automated visual inspection of printed circuit board (pcb) (or lcd, transistor) manufacture where a camera autonomously scans the device under test for both catastrophic failure (e.g. missing component) and quality defects (e.g. fillet size or shape or component skew). it is commonly used in the manufacturing process because it is a non contact test.

Comments are closed.