Applying Supply Chain Resilience Levers Flex

Applying Supply Chain Resilience Levers Flex Applying supply chain resilience levers. a previous post in this supply chain resilience blog series made the case that profound global risks — currently exemplified by the covid 19 pandemic — have put us at an inflection point. this moment has become a rallying point to fortify our end to end manufacturing ecosystems as covid 19 has laid. Resilient supply chains via digitization. this is the third installment of our blog series, the supply chain resilience imperative. in this post, we explore how digital transformation can be a powerful lever in building resilient supply networks. is 2020 the breakout year for supply chain digitization?.

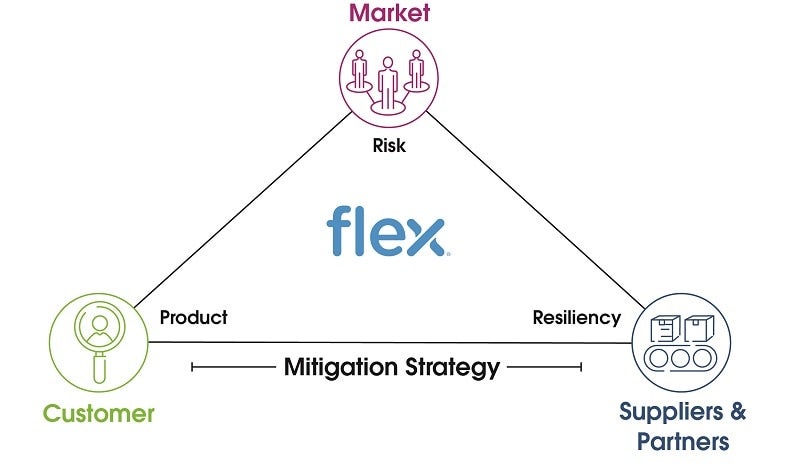

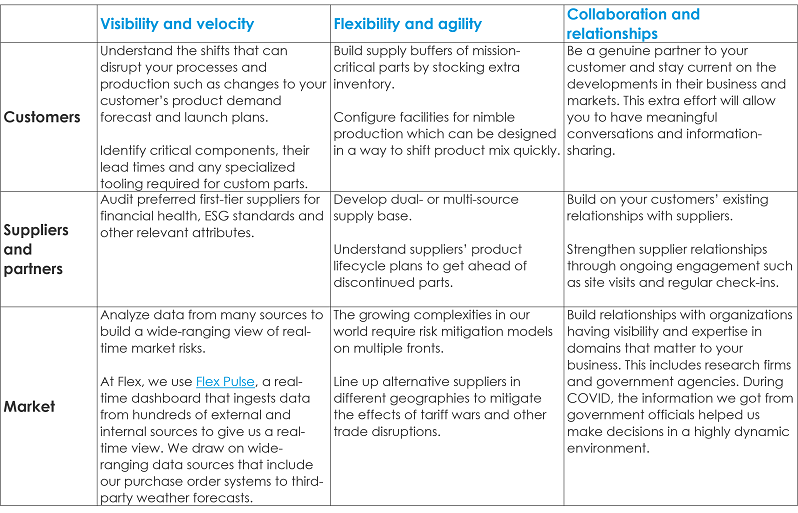

Applying Supply Chain Resilience Levers Flex How applying various supply chain resilience levers helped us persevere amid covid 19 disruptions by lynn torrel as an organization managing some 1,000 supply chains on our customers’ behalf, flex is constantly evaluating our risk mitigation models. we identify, evaluate and mitigate risks through three lenses: serving our customers: understanding our obligations to customers requires an…. As these companies seek to rebalance their supply chains for greater resiliency, reliability, and agility, they are increasingly turning to partners who offer global scope, scale, and cross industry experience while helping them deliver safe, effective, and innovative healthcare solutions that meet their requirements. Real world supply chain resilience. the covid 19 crisis has been a wake up call for supply chain managers. for years, companies have focused on eliminating redundancy in sourcing to reduce fixed costs and promote efficiency. greater efficiency, however, came at the expense of diminished flexibility and effectiveness—a tradeoff the pandemic. Strategy no. 1: inventory and capacity buffers. buffer capacity is the most straightforward way to enhance resilience, whether in the form of underutilized production facilities or inventory in excess of safety stock requirements. the challenge is that buffers are expensive, and supply chain leaders may have a hard time justifying them to the c.

Applying Supply Chain Resilience Levers Flex Real world supply chain resilience. the covid 19 crisis has been a wake up call for supply chain managers. for years, companies have focused on eliminating redundancy in sourcing to reduce fixed costs and promote efficiency. greater efficiency, however, came at the expense of diminished flexibility and effectiveness—a tradeoff the pandemic. Strategy no. 1: inventory and capacity buffers. buffer capacity is the most straightforward way to enhance resilience, whether in the form of underutilized production facilities or inventory in excess of safety stock requirements. the challenge is that buffers are expensive, and supply chain leaders may have a hard time justifying them to the c. Applying supply chain resilience levers. covid 19 has been a wake up call to restructure our supply chains for greater resilience, flexibility and agility. here's how: fal.cn 3d6xp. Designing resilience into global supply chains. after decades of refinement, it seemed that global companies had gotten supply chain management down to a science. by orchestrating complex, international networks of suppliers, factories, and logistics providers, companies had been able to squeeze out cost, get goods to distant markets with.

Comments are closed.