Advanced Automated Visual Inspection Systems For Industrial

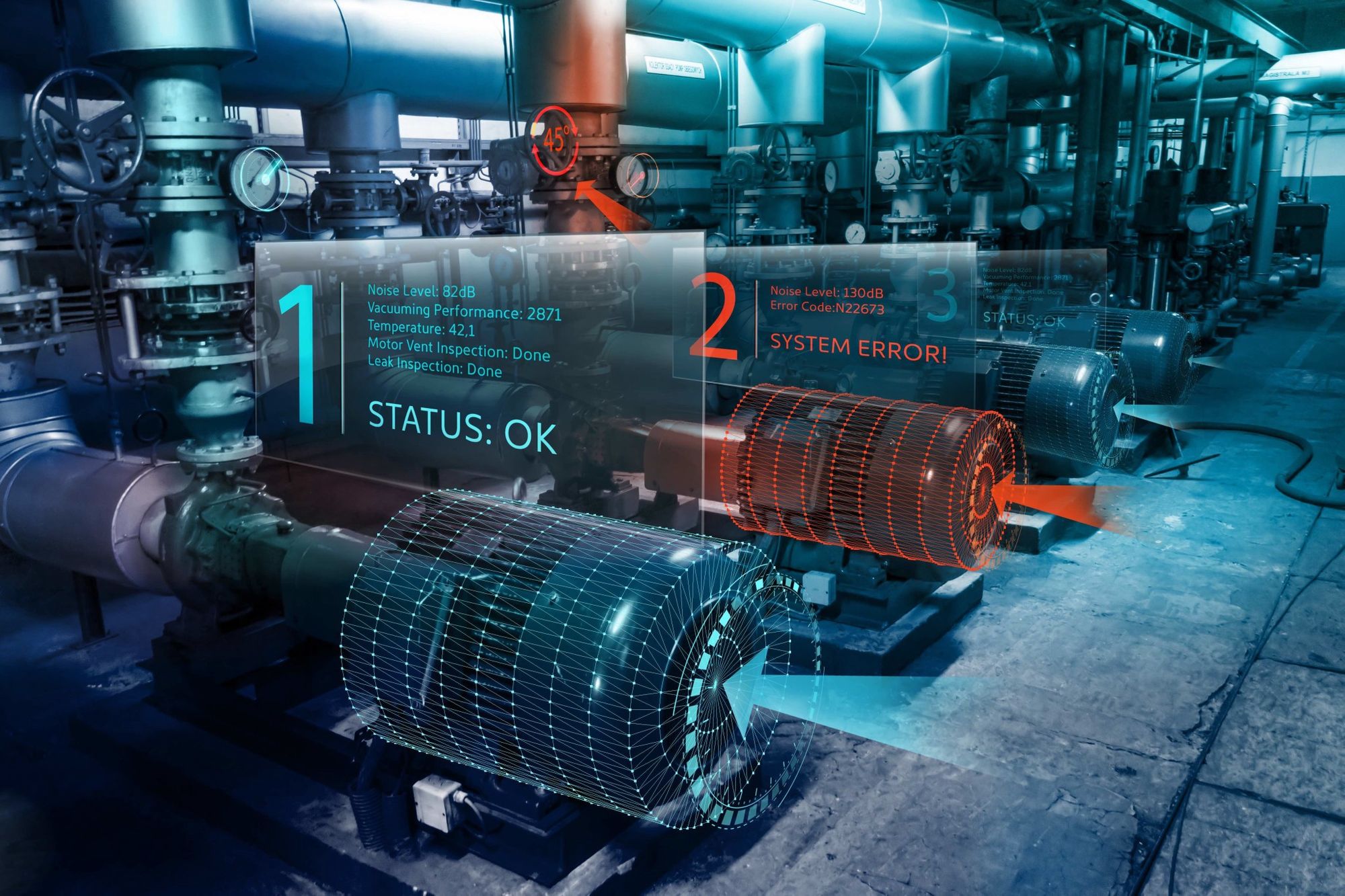

Advanced Automated Visual Inspection Systems For Industrial Ai: ai, especially deep learning algorithms, provides the automation vision inspection system with powerful image understanding and analysis capabilities. it can identify complex and minute defects — achieving highly accurate quality control. rgbd: rgbd technology combines color images and depth information to enhance automated systems with. Quality control, productivity, and efficiency through the power of automation. an automated vision inspection system (avi), also known as an automatic machine vision system or optical inspection machine, is a sophisticated machine that uses advanced imaging technology such as cameras, sensors, and image processing software to automatically.

Automated Visual Inspection Wilco Ag Vision systems are used for a variety of applications, including quality control and inspection in manufacturing, automated guidance in robotics, and even security surveillance. they utilize advanced vision systems technology such as image processing algorithms and artificial intelligence to accurately identify and analyze images or objects. Inspection robots, measurement robots & testing robots. fanuc is an industry leading provider of industrial and robotic vision inspection systems, with decades of experience and expertise. fanuc is also the only industrial robot and cobot supplier that integrates our very own unique vision system with our inspection robots every fanuc robot. We are here for you. 1 978 225 2030. contact us. allied vision helps you to find the right camera for your application in: automotive, robotics, semiconductors, photovoltaics, electronics, food & beverages and many more industrial applications. A vision inspection system is made up of an industrial camera, lens (or lenses), lighting, and an image processing unit. these systems capture images that inspect products for problems like defects, contaminants, misalignment, incorrect labeling, presence or absence of a part, or mismeasurements. vision inspection systems are used in virtually.

Automated Vision Systems Vantage Corporation We are here for you. 1 978 225 2030. contact us. allied vision helps you to find the right camera for your application in: automotive, robotics, semiconductors, photovoltaics, electronics, food & beverages and many more industrial applications. A vision inspection system is made up of an industrial camera, lens (or lenses), lighting, and an image processing unit. these systems capture images that inspect products for problems like defects, contaminants, misalignment, incorrect labeling, presence or absence of a part, or mismeasurements. vision inspection systems are used in virtually. The inspect.assembly solution is a fully integrated inspection station that utilizes a radiant vision systems prometric ® y series imaging system, bright field lighting, and programmable inspection software to detect subtle, low contrast defects on complex assemblies. the system can be easily added to the production line to accommodate real. The software layer is essential for automated visual inspection systems. it uses advanced image processing algorithms to inspect products, adjust image quality, and identify defects based on.

Everything You Need To Know About Visual Inspection With Ai The inspect.assembly solution is a fully integrated inspection station that utilizes a radiant vision systems prometric ® y series imaging system, bright field lighting, and programmable inspection software to detect subtle, low contrast defects on complex assemblies. the system can be easily added to the production line to accommodate real. The software layer is essential for automated visual inspection systems. it uses advanced image processing algorithms to inspect products, adjust image quality, and identify defects based on.

Comments are closed.