5s

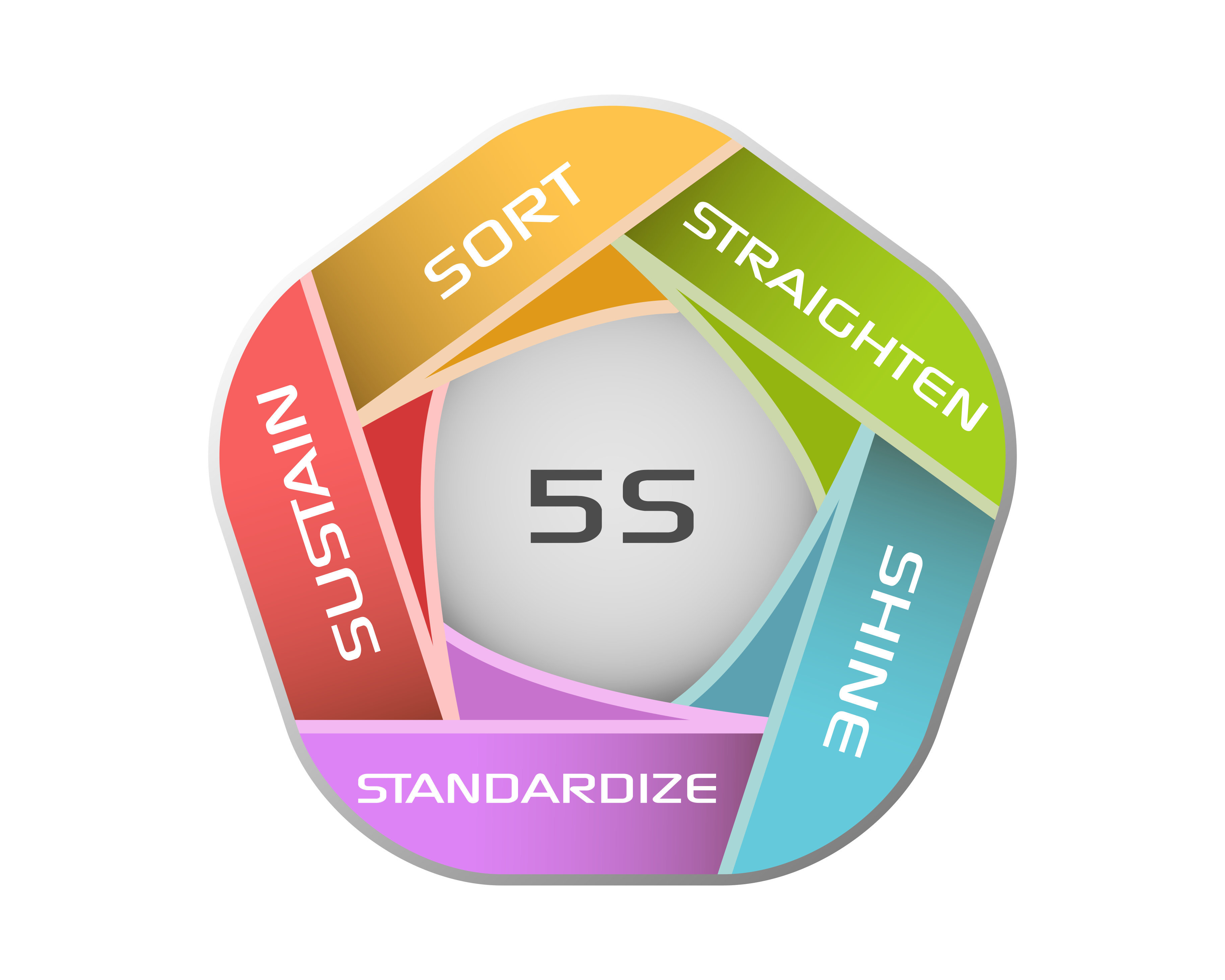

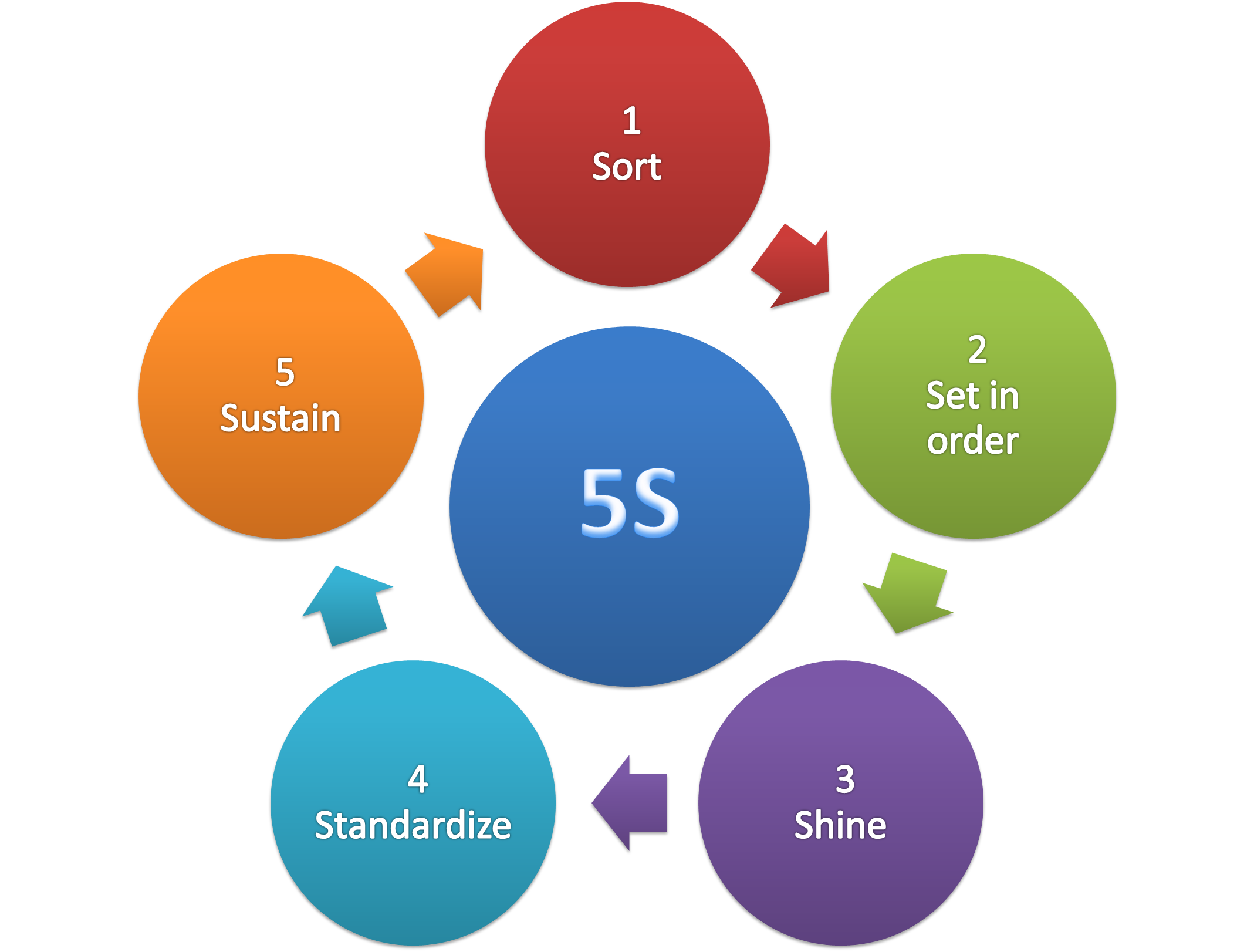

Lean 5s Six Sigma Safety Science 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. it's designed to help build a quality work environment, both physically and mentally. the 5s philosophy applies in any work area suited for visual control and lean production. 5s involves assessing everything present in a space, removing what's unnecessary, organizing things logically, performing housekeeping tasks, and keeping this cycle going. organize, clean, repeat. let's take a closer look at each of the parts of 5s. Learn how to organize and manage your workspace with 5s, a lean manufacturing tool that eliminates waste and improves efficiency. 5s stands for sort, set, shine, standardize and sustain, and involves five steps to create a clean, safe and effective environment. 5s is a philosophy applied in the workplace that helps promote efficiency and effectiveness. as one of the core principles of kaizen, 5s lean principles can help identify and eliminate wastage to achieve a well organized and safe working environment.

What Is 5s And How Should We Implement It вђ 5s Today Learn how to organize and manage your workspace with 5s, a lean manufacturing tool that eliminates waste and improves efficiency. 5s stands for sort, set, shine, standardize and sustain, and involves five steps to create a clean, safe and effective environment. 5s is a philosophy applied in the workplace that helps promote efficiency and effectiveness. as one of the core principles of kaizen, 5s lean principles can help identify and eliminate wastage to achieve a well organized and safe working environment. Learn what 5s is, why it is important and how to implement it in your workplace. 5s is a standardized process that creates and maintains an organized, safe, clean and efficient work environment. 5s is a structured methodology designed to create and maintain a well organized, clean, and efficient workplace. originating from japan, it is one of the foundational tools in lean manufacturing, focusing on eliminating waste and improving operational efficiency.

File 5s Methodology Png Learn what 5s is, why it is important and how to implement it in your workplace. 5s is a standardized process that creates and maintains an organized, safe, clean and efficient work environment. 5s is a structured methodology designed to create and maintain a well organized, clean, and efficient workplace. originating from japan, it is one of the foundational tools in lean manufacturing, focusing on eliminating waste and improving operational efficiency.

Comments are closed.