5 S

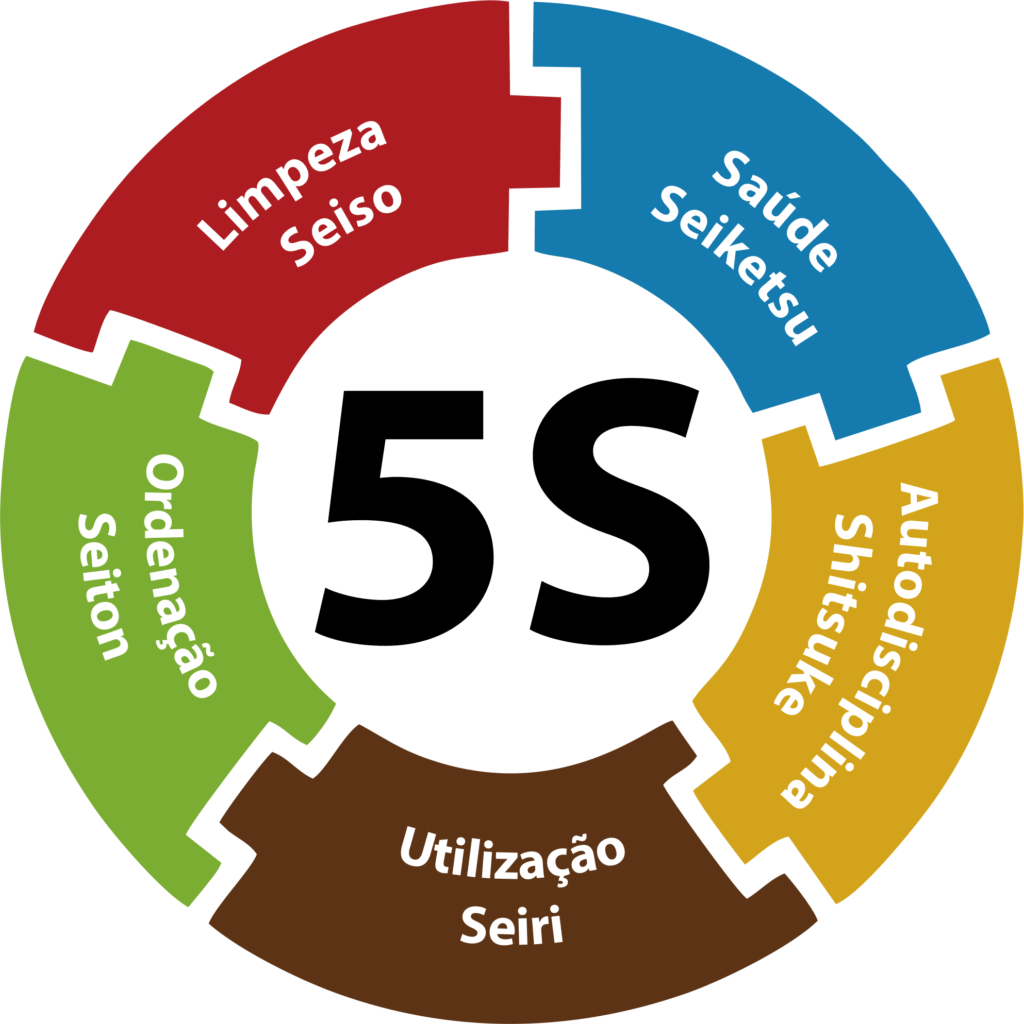

Curso De 5s Implementação Do Programa 5s Quality glossary definition: five s’s (5s) 5s is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. it's designed to help build a quality work environment, both physically and mentally. the 5s philosophy applies in any work area suited for. 5s (methodology) 5s (five s) is a workplace organization method that uses a list of five japanese words: seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾). these have been translated as 'sort', 'set in order', 'shine', 'standardize', and 'sustain'. [1] the list describes how to organize a work space for.

Programa 5s Confira O Que é E Como Funciona Sou Secretária Product waste (shavings, containers, liquids, wrappers, etc.) are consistently and regularly cleaned and disposed of; preventive measures are implemented to ensure the workplace adheres to 5s guidelines; the work environment provides sufficient lighting, comfortable temperatures, sufficient air flow and quality, etc.;. Tip #1: to help sustain 5s practices, make sure all new employees (or employees who switch departments) receive training about their area's 5s procedures. tip #2: keep things interesting. look at what other companies are doing with 5s. new ideas for organization can keep things improving and keep employees engaged. 5s is a five step methodology that, when followed, creates a more organized and productive workspace. in english, the 5s’s are: sort, straighten, shine, standardize, and sustain. 5s serves as a foundation for deploying more advanced lean production tools and processes. what is the 5s methodology?. 5s is a structured methodology designed to create and maintain a well organized, clean, and efficient workplace. originating from japan, it is one of the foundational tools in lean manufacturing, focusing on eliminating waste and improving operational efficiency. the five steps of 5s—sort, set in order, shine, standardize, and sustain.

5s Methodology Erising 5s is a five step methodology that, when followed, creates a more organized and productive workspace. in english, the 5s’s are: sort, straighten, shine, standardize, and sustain. 5s serves as a foundation for deploying more advanced lean production tools and processes. what is the 5s methodology?. 5s is a structured methodology designed to create and maintain a well organized, clean, and efficient workplace. originating from japan, it is one of the foundational tools in lean manufacturing, focusing on eliminating waste and improving operational efficiency. the five steps of 5s—sort, set in order, shine, standardize, and sustain. Learn how to organize and manage your workspace with 5s, a lean manufacturing tool that eliminates waste and improves efficiency. 5s stands for sort, set, shine, standardize and sustain, and involves five steps to create a clean, safe and effective environment. The concept of 5s. 5s is a methodical way to organize your workplace and your working practices as well as being an overall philosophy and way of working. it is split into 5 phases, each named after a different japanese term beginning with the letter “s”; (seiri, seiton, seiso, seiketsu, shitsuke) hence the name 5 s.

Comments are closed.