A History Of Mrp

How To Understand The History Of Mrp And Drp Brightwork Research Material requirements planning. material requirements planning (mrp) is a production planning, scheduling, and inventory control system used to manage manufacturing processes. most mrp systems are software based, but it is possible to conduct mrp by hand as well. an mrp system is intended to simultaneously meet three objectives:. The history of material requirements planning the implementation and constant innovation surrounding the mrp inventory system created a long lasting effect that can still be seen today. before computer engineered systems became prevalent in the business world, inventory was recorded by hand.

A History Of Mrp Youtube History of mrp . material requirements planning was the earliest of the integrated information technology (it) systems that aimed to improve productivity for businesses by using computers and. This era also saw mrp systems evolve to become more user friendly and capable of handling larger amounts of data. the 1980s: mrp ii and computer advancements. the term mrp ii (manufacturing resource planning) was coined to describe systems that expanded beyond material requirements to include additional manufacturing processes. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. mrp converts the master schedule of production into a detailed schedule, so that you can purchase raw materials and components. used mostly in the manufacturing and fabrication industries, this system is a push type of inventory. Manufacturing resource planning (mrp ii) [1] is a method for the effective planning of all resources of a manufacturing company. ideally, it addresses operational planning in units, financial planning, and has a simulation capability to answer " what if " questions and is an extension of closed loop mrp (material requirements planning).

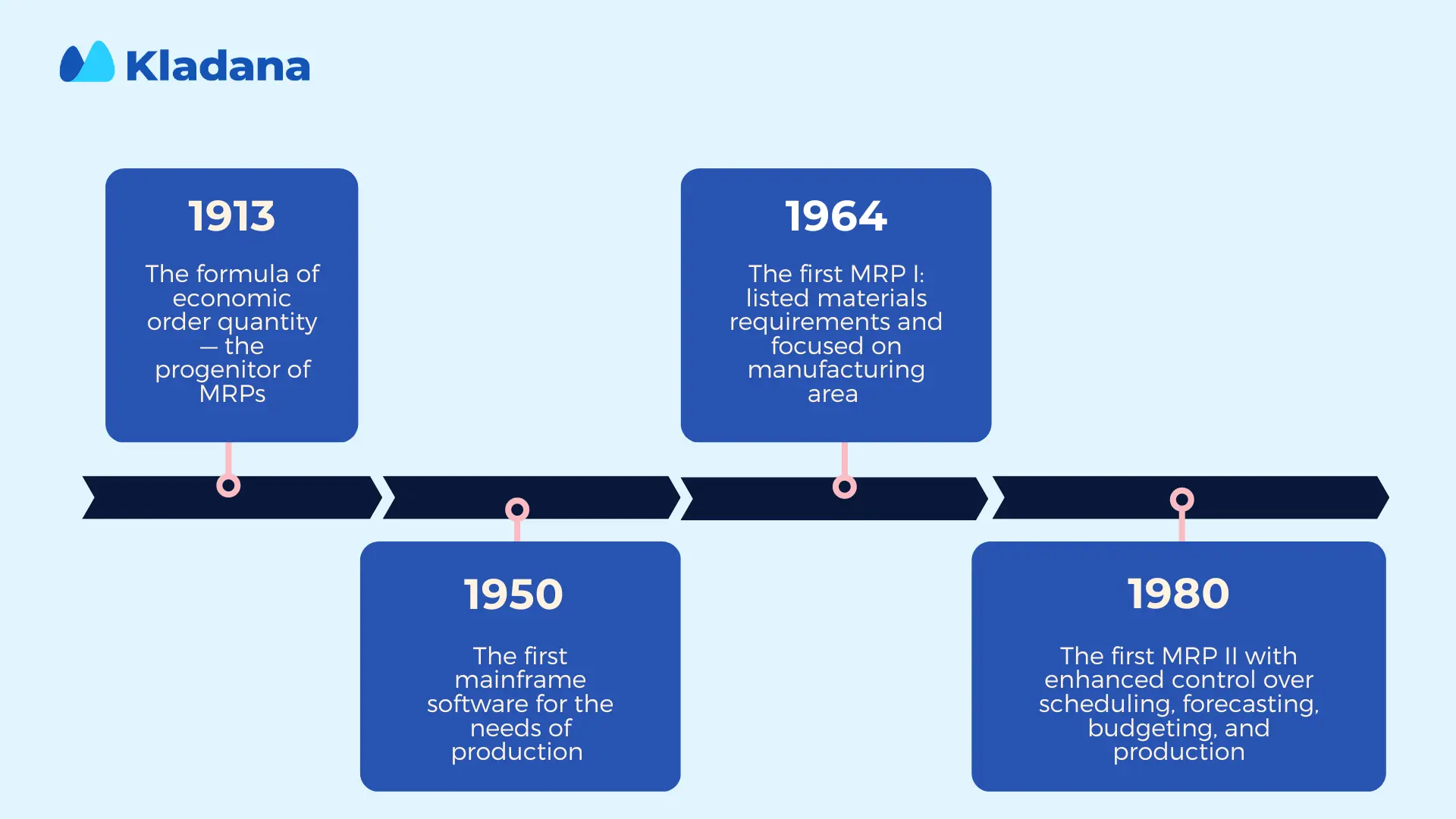

What Is Material Requirements Planning Mrp Cin7 Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. mrp converts the master schedule of production into a detailed schedule, so that you can purchase raw materials and components. used mostly in the manufacturing and fabrication industries, this system is a push type of inventory. Manufacturing resource planning (mrp ii) [1] is a method for the effective planning of all resources of a manufacturing company. ideally, it addresses operational planning in units, financial planning, and has a simulation capability to answer " what if " questions and is an extension of closed loop mrp (material requirements planning). What is the history of mrp? in the early 20th century, mrp began to take shape with new approaches to streamline manufacturing. in 1913, an american production engineer named ford whitman harris created a formula called economic order quantity. it helped minimize the costs of ordering and storing goods. 1. introduction to mrp. mrp, or material requirements planning, is a software based integrated inventory and supply management system designed for businesses. it is used to plan manufacturing, procurement, and delivery schedules for components, materials, and finished products, based on customer demand. the main objective of mrp is to ensure.

Mrp Material Requirements Planning Systems Operation Process Basic What is the history of mrp? in the early 20th century, mrp began to take shape with new approaches to streamline manufacturing. in 1913, an american production engineer named ford whitman harris created a formula called economic order quantity. it helped minimize the costs of ordering and storing goods. 1. introduction to mrp. mrp, or material requirements planning, is a software based integrated inventory and supply management system designed for businesses. it is used to plan manufacturing, procurement, and delivery schedules for components, materials, and finished products, based on customer demand. the main objective of mrp is to ensure.

Ppt Chapter 15 Resource Planning Powerpoint Presentation Free

Comments are closed.