3d Printed Mold Tooling New Equipment Digest

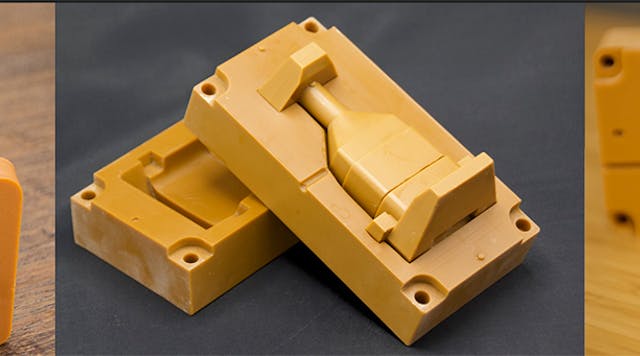

3d Printed Mold Tooling New Equipment Digest Learning center. 3d printed mold tooling. april 18, 2022. the fast, inexpensive solution for prototype and low volume molding. injection molding has become the go to manufacturing solution for plastic components. used in a variety of industries, the injection molding market is poised for continued aggressive growth driven by trends such as the. So what we’re trying to bring is this new additive manufacturing technology to these mold makers to provide them a new tool to make better components.” in terms of industrialization of the technology, 3d printing molds is a perfect start. as ledvon explains, mold makers are already pushing the limits of traditional machining.

3d Printed Mold Tooling New Equipment Digest He previously wrote about equipment and fleet operations and management for fleetowner, and prior to that, manufacturing and advanced technology for industryweek and new equipment digest. he is an award winning journalist and former sonar technician aboard a nuclear powered submarine where he served honorably aboard the fast attack submarine. 3d printed tooling is taking off. additive manufacturing is overcoming early hurdles to become a viable option for mold making in many industries. a decade ago, manufacturing large composite tooling was generally an expensive, months long process. but things began to change in 2014, when the u.s. department of energy’s oak ridge national. Its 3d printers from plural additive manufacturing basically run around the clock to create custom masking tooling tailored to the parts pmt will be coating with metal. 10. gate precast: forms for precast concrete panels. this example showcases gate precast, a precast concrete manufacturer in winchester, kentucky. While many metal 3d printing methods have established a niche in their respective applications – for example, powder bed fusion for medical implants or binder jet for mim components – tooling has long been a target for various approaches. this white paper serves as a guide to understanding the major metal 3d printing technologies and their role in printing injection mold tooling.

3d Printed Mold Tooling New Equipment Digest Its 3d printers from plural additive manufacturing basically run around the clock to create custom masking tooling tailored to the parts pmt will be coating with metal. 10. gate precast: forms for precast concrete panels. this example showcases gate precast, a precast concrete manufacturer in winchester, kentucky. While many metal 3d printing methods have established a niche in their respective applications – for example, powder bed fusion for medical implants or binder jet for mim components – tooling has long been a target for various approaches. this white paper serves as a guide to understanding the major metal 3d printing technologies and their role in printing injection mold tooling. It’s not uncommon for a machined tool to cost $45,000 and take six to eight weeks to complete. the same mold, 3d printed, will cost about $2,000 and is made in a matter of hours to one week. 3d printing molds with metal paste: the mantle process explained (video) metal paste is the starting point for a process using 3d printing, cnc shaping and sintering to deliver precise h13 or p20 steel tooling for plastics injection molding. peter zelinski talks through the steps of the process in this video filmed with mantle equipment. watch.

3d Printed Mold Tooling New Equipment Digest It’s not uncommon for a machined tool to cost $45,000 and take six to eight weeks to complete. the same mold, 3d printed, will cost about $2,000 and is made in a matter of hours to one week. 3d printing molds with metal paste: the mantle process explained (video) metal paste is the starting point for a process using 3d printing, cnc shaping and sintering to deliver precise h13 or p20 steel tooling for plastics injection molding. peter zelinski talks through the steps of the process in this video filmed with mantle equipment. watch.

Comments are closed.